“`html

Smart Ways to Drywall Like a Professional in 2025: Enhance Your Skills Today

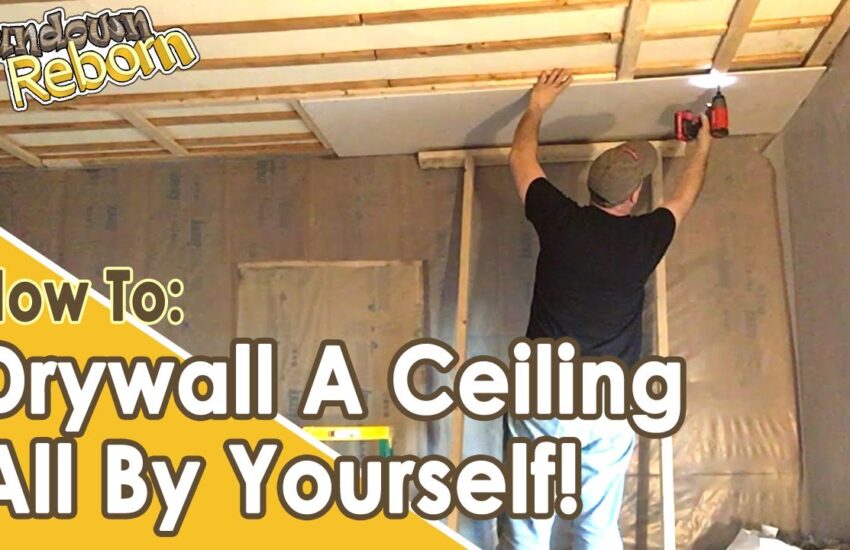

Whether you’re a DIY enthusiast or a professional contractor, mastering the art of drywall can significantly elevate your construction or renovation projects. In this article, you will explore top-notch techniques for effective drywall installation, finishing, repair, and maintenance that will help you achieve a professional finish in 2025. Let’s dive into advanced drywall methods, tools, and best practices to refine your skills.

Essential Drywall Tools for Professional Quality Installation

When it comes to **drywall installation**, using the right tools is paramount. High-quality tools not only streamline the process but also enhance your final results. At the minimum, you’ll need essential drywall tools like **drywall screws**, **drywall tape**, and **drywall mud**. Additionally, investing in a reliable drywall lift can greatly facilitate the hanging process, especially for ceiling work. Each tool has its specific purpose, ensuring that each phase of the installation, from **drywall framing** to **drywall finishing**, is executed flawlessly.

Advantages of Using Professional Drywall Tools

Utilizing professional-grade drywall tools provides several benefits, including increased efficiency and better precision. For instance, a cordless drywall screw gun significantly speeds up the hanging process and ensures your **drywall screws** are driven consistently. Similarly, high-quality **drywall mudding** equipment enables smoother finishes, reducing the need for extensive sanding after the installation. Moreover, every tool plays a crucial role in achieving the desired depth and finish of the **drywall seams**. Investing in tools like electric sanders can save time and deliver a professional look with less effort.

Comprehensive Drywall Tools List

Here is a comprehensive list of essential drywall tools that every professional installer should have on hand:

- Drywall lift

- Drywall screws and screw gun

- Drywall taping knife

- Utility knife for **drywall cutting**

- Portable sander or drywall sanding pole

- Measuring tape and straight edge

- Joint compound mixing paddle

- Tape measure for accurate **drywall dimensions**

- Corner bead tool for perfect finishes at joints

- Dust mask and safety glasses for **drywall safety**

Equipping yourself with these tools emphasizes your commitment to delivering high-quality results, elevating your work above DIY standards.

Understanding Drywall Finishing Techniques

**Drywall finishing** is crucial to achieving a seamless appearance in your projects. This process goes beyond simply hanging the sheets; it’s about creating an elegant, smooth surface ready for painting or texturing. A thorough understanding of **drywall finishing techniques** can prevent common mistakes that compromise the look of your work. The finishing phase involves sanding, applying primer, and potentially texturing, all of which contribute to the final aesthetics of the structure.

Popular Drywall Finishing Techniques

Many drywall professionals utilize various finishing techniques that affect both the surface finish and preparation for paint. One popular technique is the **skim coat**, involving applying a thin layer of joint compound over the entire drywall surface. This not only evens out imperfections but also enhances the overall durability of the wall. Additionally, sophisticated textures, such as knockdown or slap brush techniques, can add visual interest and mask minor flaws.

Step-by-Step Guide to Efficient Drywall Finishing

To ensure a flawless drywall finish, follow these key steps:

- **Apply a coat of joint compound** across all seams and screw holes using your taping knife.

- Let the compound dry completely, refer to manufacturer’s guidelines regarding drying time.

- **Sand** the entire area using a drywall sander, focusing on any raised spots or imperfections.

- **Apply a second layer** of joint compound to further smooth the surface, then let it dry and sand again.

- After achieving a smooth finish, use a quality primer to seal the drywall before painting.

Each of these steps requires attention to detail and the right tools to ensure a flawless finish.

Advanced Drywall Techniques for Unique Projects

Incorporating advanced **drywall techniques** into your projects can set you apart from the competition. Utilizing styles such as **drywall for soundproofing** or installing moisture-resistant varieties can enhance the functionality and durability of the structures you work on. Advanced knowledge of these areas allows you to cater to specific client needs, enhancing customer satisfaction and repeat business.

Drywall Techniques for Soundproofing

Implementing drywall techniques that aid in soundproofing can substantially benefit residential and commercial projects alike. For example, using denser drywall products, such as soundproofing boards, combined with acoustic caulking, can significantly reduce noise transfer. Incorporating extra layers of drywall in specific patterns can also act as a sound barrier without dramatically changing the look of the walls. When planning soundproof drywall installation, consider the layout and type of occupancy that will use the space, helping you design a solution that effectively meets the needs.

Drywall Installation for Unique Shapes

Working with unique shapes or custom designs can be a rewarding challenge when it comes to drywall installation. Techniques like **drywall curving** for archways or using smaller sheets to adapt to intricate angles can enhance the overall design of a space. Having knowledge about different cutting methods, including scoring and snapping, allows for adaptability during **drywall installation process**, ensuring that your project remains on track and visually appealing.

Drywall Maintenance and Repair Techniques

Understanding maintenance and repair techniques for drywall is crucial in preserving the appearance and integrity of your work. Simple tasks such as timely spot-repairing cracks or moisture-damaged areas prevent larger problems from arising, ensuring longevity for every installation you complete. Training in efficient drywall repair techniques can save clients on costs and unnecessary renovations while highlighting your expertise.

Effective Drywall Repair Techniques

Repairing damaged drywall involves specific methods that yield satisfying results. Small holes can often be repaired with **drywall patching** using a pre-cut patch or compound alone, while larger damaged areas may necessitate replacing entire sections. When patching, ensure you feather out the joint compound—blending the new with the old—for a seamless repair. Post-repair, thorough sanding followed by repainting is essential in returning the wall to its original state, providing durability and aesthetic appeal.

Developing a Routine for Drywall Maintenance

Establishing a routine maintenance plan for drywall can prevent issues related to moisture, mold, or damage. Routine inspections of wet areas or high-traffic spaces can help identify early signs of wear. Regular repainting can keep drywall looking fresh while addressing any deep-seated problems with the underlying structure or finish will prolong wall lifespan. Providing clients with a clear maintenance checklist further enhances value and service quality.

Key Takeaways

- Building expertise in drywall tools aids precision and efficiency in installations.

- Mastering drywall finishing techniques leads to professional-grade wall surfaces.

- Utilize advanced drywall techniques to broaden service offerings.

- Understanding maintenance and repair can help ensure the longevity of drywall installations.

FAQ

1. What is the best drywall installation method for beginners?

The best drywall installation method for beginners is the traditional hanging method, where drywall sheets are attached horizontally to the studs using **drywall screws**. It’s essential to ensure that every screw is countersunk to avoid any protruding heads, leading to a smoother finish during the sanding and painting phases.

2. How do you prevent moisture issues in drywall?

To prevent moisture issues in drywall, consider using moisture-resistant drywall panels in spaces like kitchens and bathrooms. Additionally, applying a vapor barrier in high-humidity environments and regularly inspecting for leaks can help mitigate water damage risks.

3. What are common mistakes during drywall installation?

Common mistakes during drywall installation include improper cutting techniques, uneven application of **drywall mud**, and neglecting to adequately measure before cutting. Failing to address these areas can lead to callbacks for repairs and negatively affect the overall finish quality.

4. How do I choose the right type of drywall for a project?

Selecting the right type of drywall involves analyzing the project requirements such as moisture resistance for bathrooms and fire resistance for garages. Regular drywall is adequate for most walls but consider specialized types for areas prone to specific issues to optimize performance.

5. What are the advantages of using a drywall lift?

Using a drywall lift offers several advantages, including enhanced safety by eliminating the need for ladders and enabling easy lifting of heavy panels overhead. This tool significantly speeds up the hanging process, especially on ceilings, facilitating a smoother workflow overall.

“`